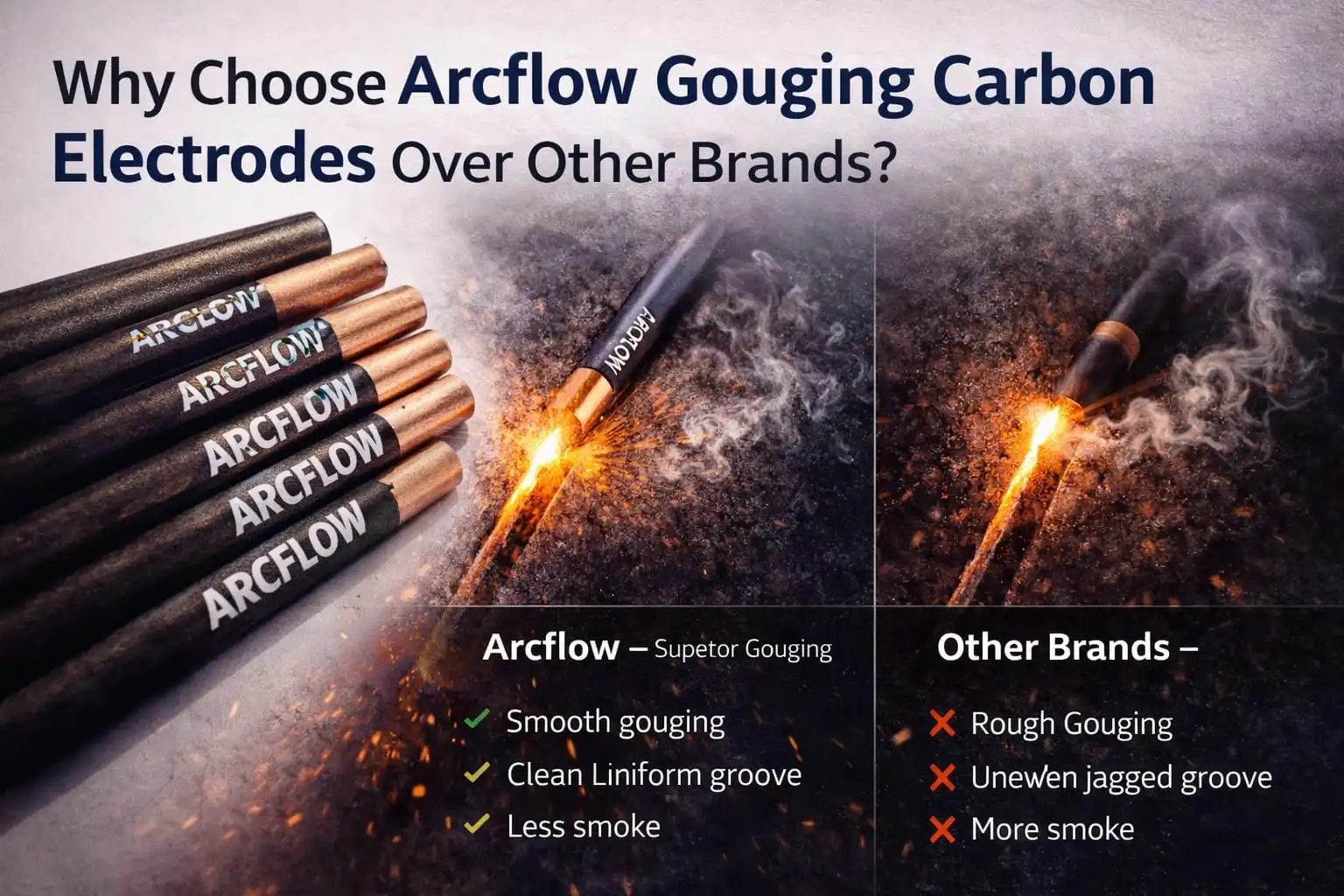

Why Choose Arcflow Gouging Carbon Electrodes Over Other Brands? What Makes It Better ?

When it comes to stuff like removing metal, getting weld joints ready, or fixing defects, the quality of your Gouging carbon electrodes really makes a difference in how fast you work, how much it costs, and how good the final look is Arcflow Industries really shines by offering a 355mm gouging carbon rod, which gives pros a serious edge over the usual standard-length electrodes from other brands.

If you are comparing options in the market, here’s why Arcflow should be your preferred choice.

Understanding Gouging Carbon Electrodes

Gouging carbon electrodes are used in air carbon arc gouging to remove metal quickly and precisely. These electrodes create an arc between the carbon rod and the workpiece, melting the metal, while compressed air blows away molten material.

Whether you call it a gouging welding electrode, gouging welding rod, or arc gouging carbon electrodes, the purpose remains the same — efficient metal removal with controlled precision.

Industries that rely heavily on gouging include:

- Heavy fabrication

- Shipbuilding

- Steel structure manufacturing

- Foundries

- Repair and maintenance workshops

In such demanding environments, electrode quality and length matter more than most buyers realize.

The 355mm Advantage – Why Length Matters

Most brands in the market supply shorter electrodes. Arcflow offers a 355mm gouging carbon rod, which provides several practical advantages:

1️⃣ Longer Working Time

A longer electrode means fewer changeovers during operation. This reduces downtime and increases productivity, especially in high-volume projects.

2️⃣ Better Cost Efficiency

Even when comparing gouging electrode price, the 355mm length offers better value per rod because it lasts longer than shorter alternatives.

3️⃣ Improved Operator Convenience

Frequent replacement interrupts workflow. With a longer rod, operators can work continuously with improved comfort and consistency.

4️⃣ Higher Output in Industrial Applications

For industries performing continuous gouging operations, the extended size improves overall job efficiency.

Precision Manufacturing & Quality Control

Arcflow is known among leading gouging carbon electrodes manufacturers in India for maintaining strict quality standards. Each electrode is designed for:

- Stable arc performance

- Uniform copper coating

- Consistent carbon composition

- Reduced spatter

- Smooth metal removal

Proper gouging electrode specification ensures dependable performance across different amperage ranges and metal thicknesses.

Wide Range of Gouging Electrode Sizes

Choosing the correct gouging electrode size is critical for achieving accurate results. Arcflow offers multiple diameter options to suit different industrial requirements.

Typical sizes include:

- 6mm

- 8mm

- 10mm

- 12mm

- 16mm

The 355mm length combined with these diameter variations provides flexibility for light, medium, and heavy-duty operations.

Performance Compared to Other Brands

When comparing Arcflow to generic brands, the differences become clear:

Feature | Standard Brands | Arcflow |

Length | Shorter rods | 355mm length |

Arc Stability | Inconsistent | Smooth & stable |

Copper Coating | Uneven | Uniform coating |

Productivity | Moderate | Higher output |

Cost Efficiency | Average | Better value per use |

For workshops using cutarc gouging electrode systems or compressed air setups, the performance improvement is noticeable